Successful auto collision centers prioritize collision repair best practices through leadership-driven consistency and quality. Regular training sessions keep staff updated on industry innovations and safety protocols, while standardized procedures ensure uniform, high-quality work across the board. Performance evaluations identify strengths and weaknesses, allowing tailored training to meet specific needs, ultimately streamlining operations, reducing errors, and enhancing customer satisfaction.

“In the realm of automotive service, consistent adherence to collision repair best practices is paramount for customer satisfaction and business success. This article explores effective leadership strategies that enforce these practices across various facets of a repair shop’s operations. From cultivating a culture of unwavering quality and standardization to regular training sessions and rigorous performance evaluations, discover how leaders can drive continuous improvement in collision repair services.”

- Establishing a Culture of Consistency and Quality

- Implementing Standardized Procedures for Collision Repair

- Regular Training and Performance Evaluation: The Keys to Continuous Improvement

Establishing a Culture of Consistency and Quality

In any successful auto collision center or automotive collision repair facility, establishing a culture of consistency and quality is paramount. Leadership plays a pivotal role in fostering this environment by setting clear standards and expectations. Regular training sessions on collision repair best practices ensure that every team member stays up-to-date with industry innovations and safety protocols. This commitment to continuous learning underscores the facility’s dedication to delivering top-notch service, fostering a reputation for excellence among both customers and peers.

Moreover, consistent quality control measures, such as regular inspections and performance evaluations, reinforce the importance of adherence to collision repair best practices. By integrating these practices into the day-to-day operations of auto maintenance and repair processes, leadership ensures that every job is executed with precision and care. This not only enhances customer satisfaction but also minimizes the risk of errors or rework, ultimately streamlining the entire automotive collision repair process.

Implementing Standardized Procedures for Collision Repair

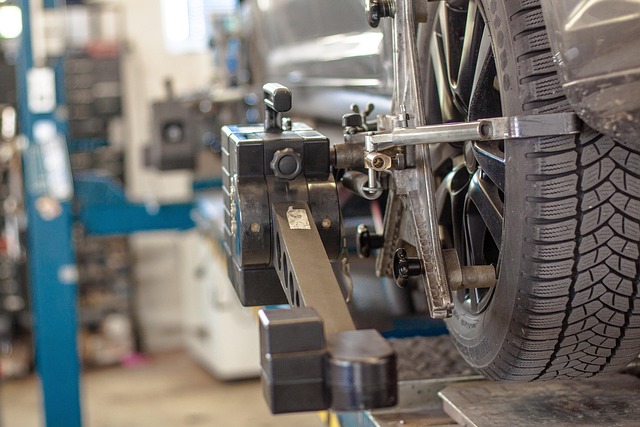

Implementing standardized procedures for collision repair is a cornerstone of fostering consistent best practices within any vehicle body shop or car body restoration facility. By establishing clear protocols for every step of the repair process—from initial assessment and damage documentation to final inspection and quality control—shop managers ensure that every technician follows the same, proven methods. This uniformity not only guarantees high-quality outcomes but also streamlines operations, reducing errors and saving time.

Standardized procedures offer numerous advantages, including improved communication among team members, as everyone is on the same page regarding best practices. They enable efficient training for new hires since they provide a clear framework to follow, ensuring that every technician reaches the same level of proficiency. Moreover, these procedures can be regularly updated based on industry advancements and feedback from experienced technicians, allowing the vehicle dent repair process to continually evolve while maintaining the highest standards.

Regular Training and Performance Evaluation: The Keys to Continuous Improvement

Regular training and performance evaluation are instrumental in maintaining collision repair best practices within any auto body shop. By scheduling consistent training sessions, leaders ensure that their teams stay up-to-date with industry advancements, new techniques, and safety protocols. This continuous learning environment fosters innovation and improves the overall quality of auto repair shop services, including car dent repair and auto body services.

Performance evaluations provide an opportunity to measure progress against these best practices. Regular feedback sessions allow leaders to identify areas where teams excel and pinpoint aspects that need improvement. Through this data-driven approach, leaders can tailor training programs to address specific gaps, ensuring every team member is equipped with the knowledge and skills required to deliver top-notch auto repair services consistently.

Effective leadership is pivotal in enforcing consistent collision repair best practices. By fostering a culture that prioritizes quality, implementing standardized procedures, and regularly training and evaluating performance, leaders ensure continuous improvement within their teams. These strategies not only enhance the overall quality of collision repair work but also create a dynamic and engaging work environment, ultimately benefitting both employees and customers.